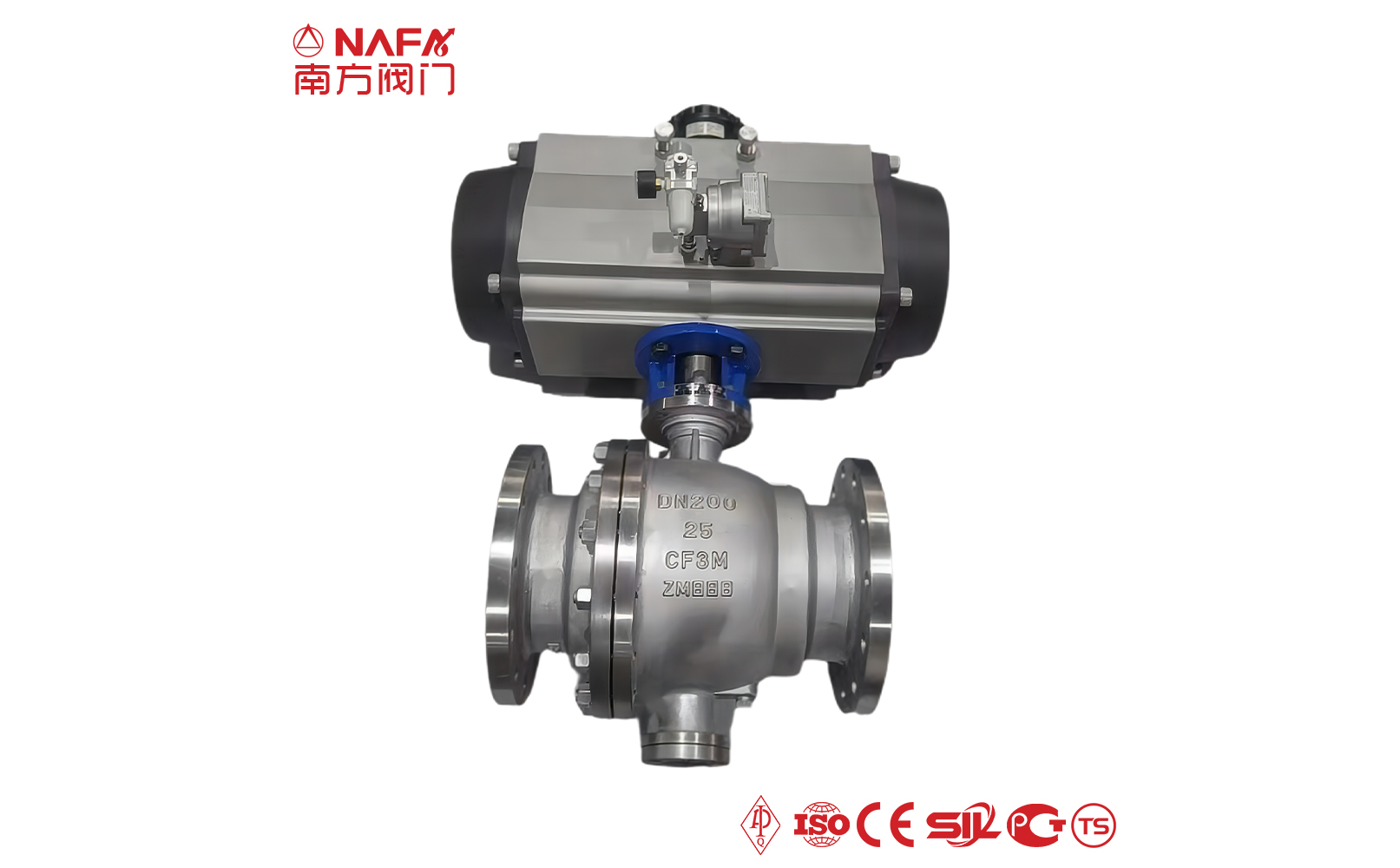

- 01The two-piece ball valve has high platform design.

- 02It has good vibration resistance, is able to meet various environmental requirements.

- 03The components of the two-piece ball valve adopt standardized design, which can be easily combined and replaced.

- 04Simple and compact structure, small fluid resistance, small opening and closing torque, and long service life.

- 05The two-piece ball valve adopts a two-piece structure, which can be easily repaired and replaced.

- 06Full-bore flow channel, small flow resistance, and greater flow capacity.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

| The characteristics of two-piece ball valve |

Two-piece ball valves also have internal thread connection, external thread connection, internal and external thread connection. The thread usually adopts 55° tapered pipe thread, which has good sealing performance. The valve stem of the two-piece ball valve has a stuffing box structure, which can be used for high-pressure medium sealing. Electric and pneumatic two-piece ball valves can realize remote control and automatic control, and the operation is convenient and reliable. In addition, it also has a wide range of applications and can meet the use requirements of various media. When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium, and it is not easy to erode the valve sealing surface when the medium passes through. |

| Advantages of two-piece ball valve |

The two-piece ball valve has high platform design. It has good vibration resistance, is able to meet various environmental requirements. The components of the two-piece ball valve adopt standardized design, which can be easily combined and replaced. Simple and compact structure, small fluid resistance, small opening and closing torque, and long service life. The two-piece ball valve adopts a two-piece structure, which can be easily repaired and replaced. Full-bore flow channel, small flow resistance, and greater flow capacity. |

| Technical Parameters | |

| Size | DN15-DN1500, 1/2''-60'' |

| Pressure | PN10-PN420, Class150-Class2500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Socket weld, Butt weld |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc |