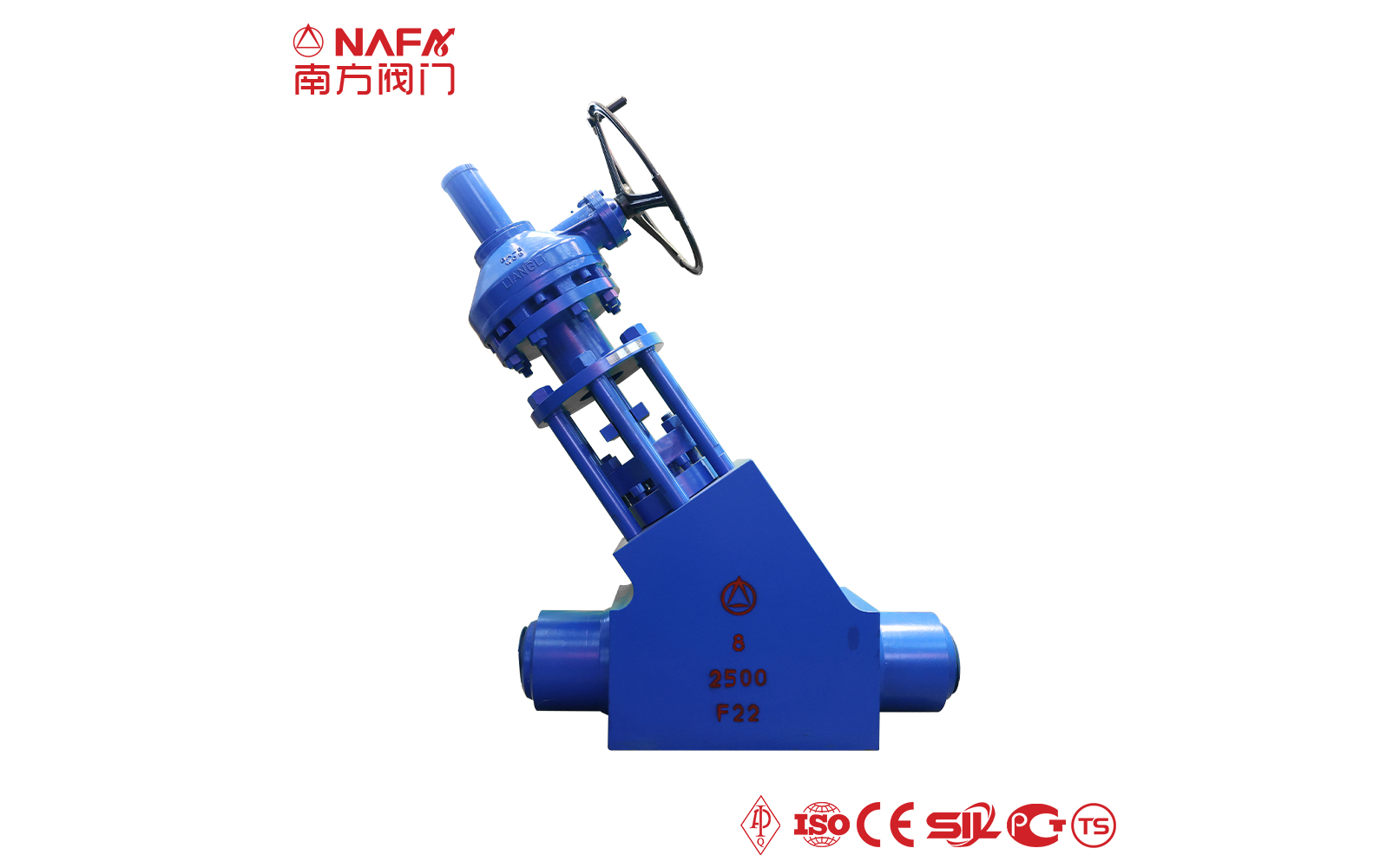

- 01It uses pressure self-tightening metal hard seal, has good sealing performance.

- 02The sealing surface of valve seat and valve flap is made of cobalt-based cemented carbide plasma spray welding, which has good wear resistance and abrasion resistance.

- 03The valve stem is treated with anti-corrosive nitriding and has good corrosion resistance.

- 04Valve cover packing box depth is reasonable, packing with corrosion inhibitor, reliable sealing.

- 05Various pipe flange standards and flange sealing surface types can be used to meet various engineering needs and user requirements.

- 06The reverse seal is made of threaded sealing seat or body surfacing welding austenitic stainless steel, reliable sealing, replacement filler can be carried out without stopping, convenient and fast, does not affect the system operation.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

| The characteristics of power station globe valve |

Low torque design. The valve stem with special structure design can be easily opened and closed with a small hand handle. Due to the use of pressure self-tightening packing seal structure, the weight of the whole valve is greatly reduced. Wedge sealing structure. The valve is sealed by the mechanical force provided by the valve stem, and the ball wedge is pressed to the seat, so that the sealing of the valve is not affected by the change of the pressure difference of the pipeline, and the sealing performance is reliably guaranteed under various working conditions. Self-cleaning structure of sealing surface. When the ball tilts away from the seat, the fluid in the pipeline passes 360 degrees evenly along the sealing surface of the ball, which not only eliminates the local erosion of the high-speed fluid on the seat, but also washes away the accumulation on the sealing surface to achieve the purpose of self-cleaning. |

| Technical Parameters | |

| Size | DN15-DN2000, 1/2''-80'' |

| Pressure | PN6-PN760, Class150-Class4500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Wafer, Welded |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc. | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc. | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc. | |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc. | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc. | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc. | |