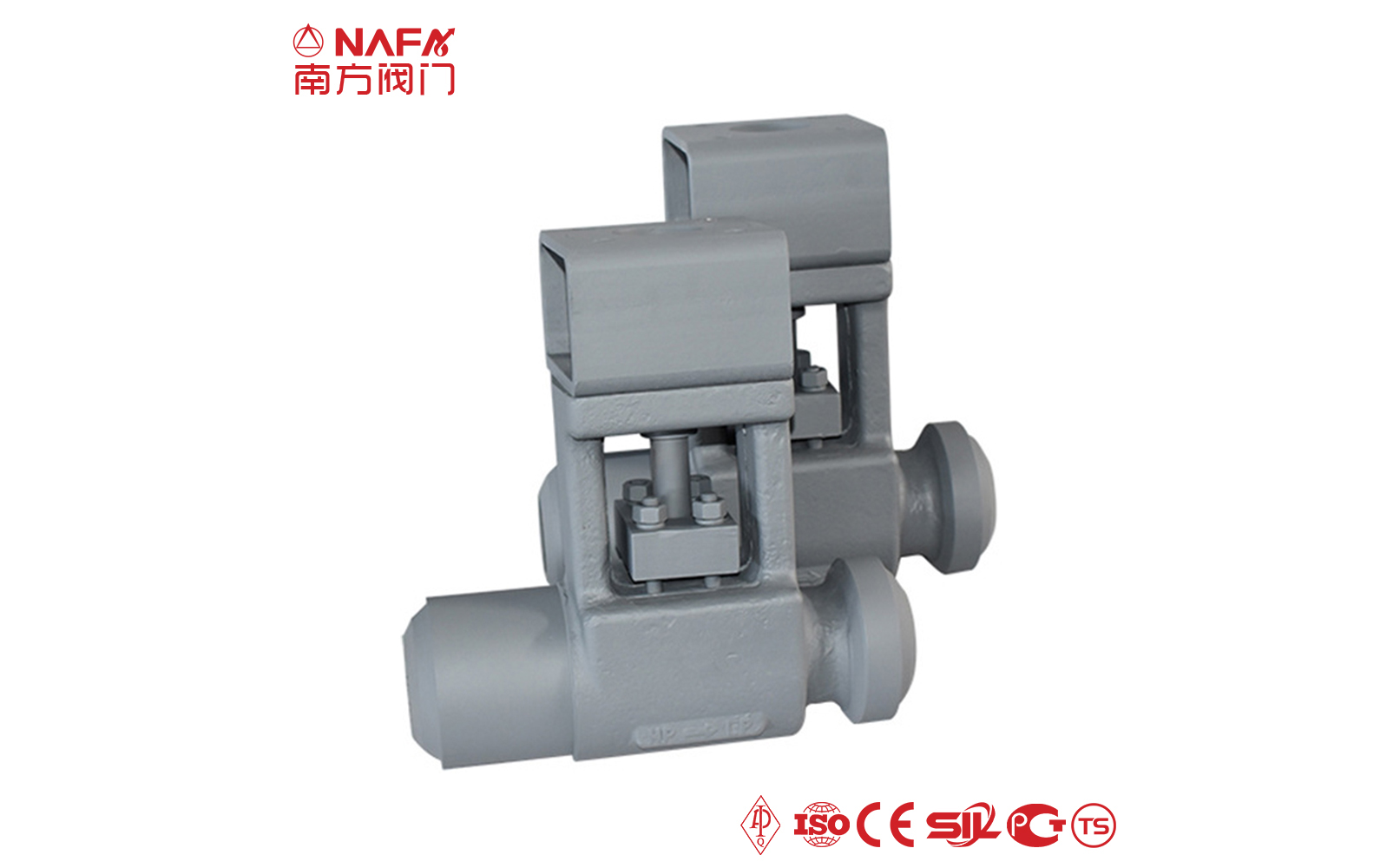

- 01Valve body integral forging, large wall thickness design, so that the valve has a best-selling service life, no external leakage.

- 02The ball and the valve seat are in interference structure, and the valve seat is embedded in the valve body from top to bottom.

- 03The valve seat adopts a wide sealing surface to reduce the stress of the sealing surface and maintain a good sealing effect during high-speed cycle operation.

- 04Fireproof design, can be used in dangerous pipeline scenarios, can reduce the risk of pipeline media leakage after a fire.

- 05Three-piece structure, the use of bolted body cover, easy to disassemble, external connection for threading and welding can be applied to a variety of working scenarios.

- 06The double seal ring can withstand higher pressure, and at the same time, different seals (such as graphite seals, PTFE and stainless steel powder seats) can be replaced to achieve higher pressure and temperature resistance.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

| The characteristics of power station ball valve |

The sealing surface of the valve ball and the sealing surface of the valve seat adopts supersonic spraying hard alloy to ensure high hardness and wear resistance of the sealing surface, and the sealing grade can reach zero leakage. The floating valve seat adopts double sealing structure design, even if one side of the valve seat seal failure due to unexpected circumstances, the valve can still work normally, thus improving the sealing reliability of the valve. The valve stem adopts anti-blow shoulder structure design, which can ensure that the valve stem will not be blown out by the medium even in the case of abnormal pressure increase in the valve chamber. The upper and lower side seats can independently cut off the medium at the inlet and outlet to achieve double blocking function, and the remaining medium in the middle cavity can be discharged through the drain valve at the bottom of the valve. |

| Technical Parameters | |

| Size | DN15-DN2000, 1/2''-80'' |

| Pressure | PN6-PN760, Class150-Class4500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Wafer, Welded |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc. | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc. | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc. | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc |