- 01Easy to operate. It can be quickly opened and closed, from full open to full close as long as the rotation of 90°, convenient remote control.

- 02Easy maintenance. The ball valve structure is simple, the sealing ring is generally active, disassembly and replacement is more convenient.

- 03Wide range of application, from high vacuum to high pressure can be applied.

- 04The channel of the segment ball valve has a self-cleaning effect, which can effectively prevent the accumulation and precipitation of the medium, thus ensuring the long-term reliable operation of the ball valve.

- 05The design of segment ball valve makes the opening and closing torque of the valve small, light operation, easy to manual operation and electric operation.

- 06Segment ball valve has good sealing performance and high reliability, which is suitable for harsh working conditions such as high temperature, high pressure and corrosive media.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

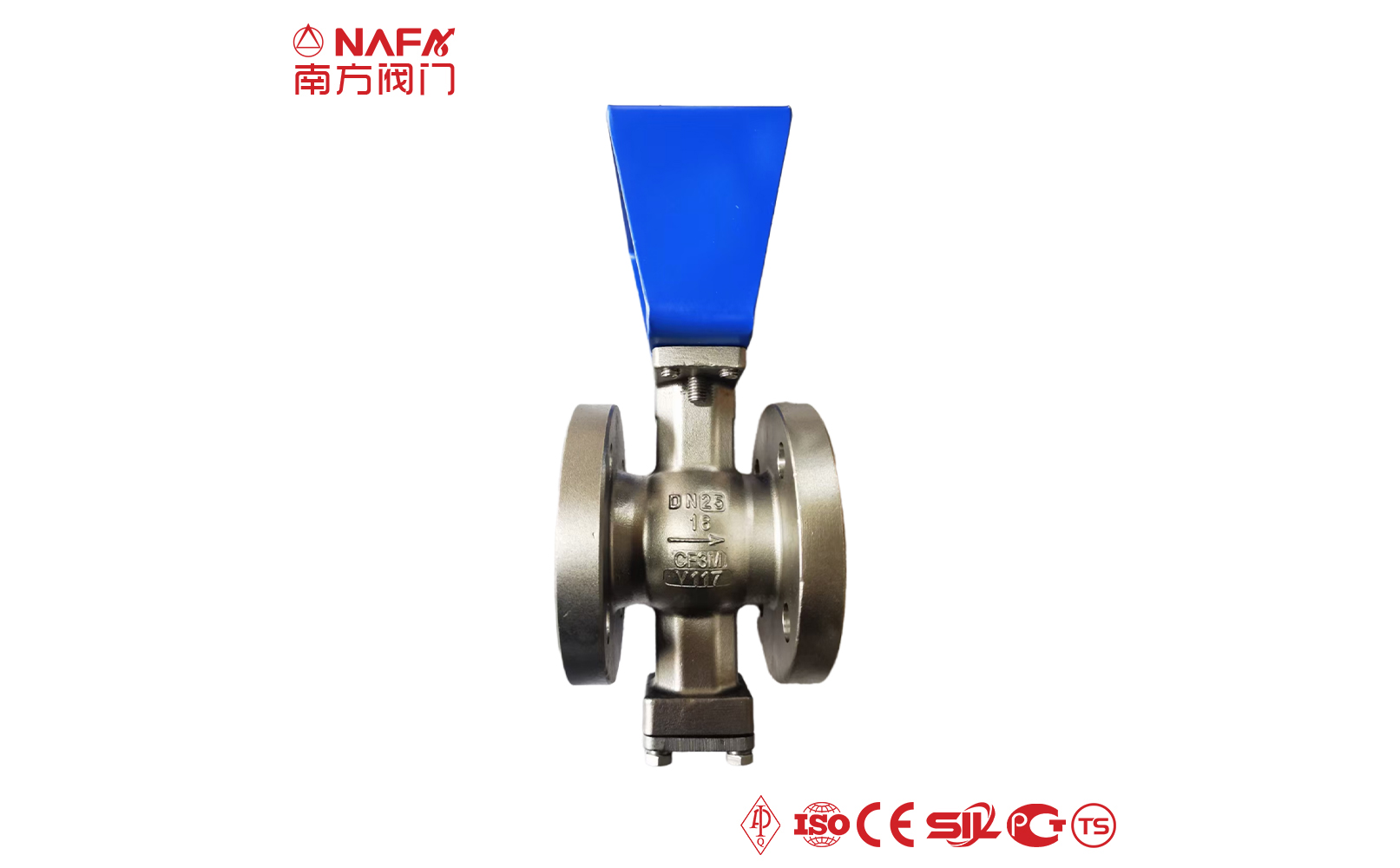

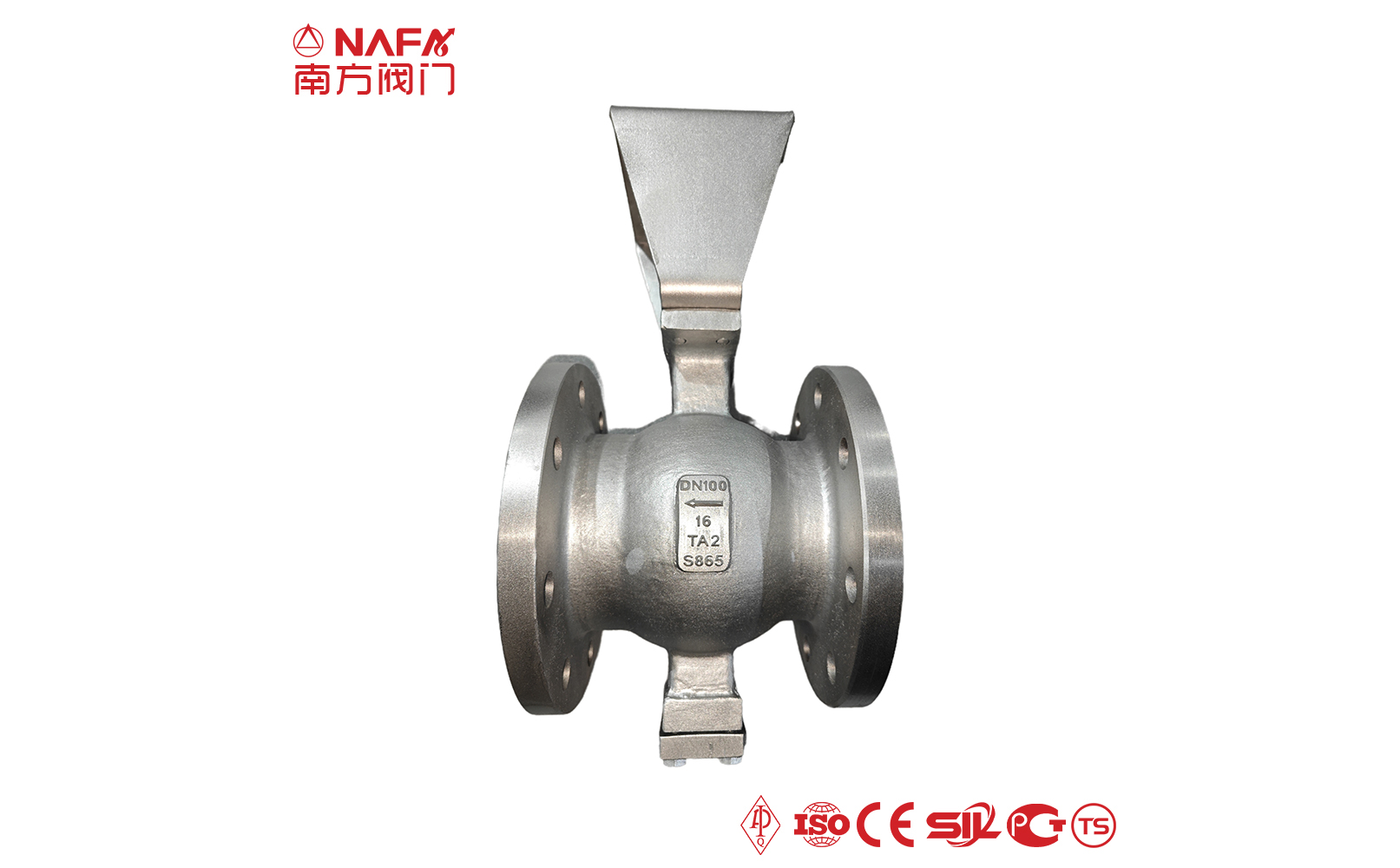

| The characteristics of segment ball valve |

The flow characteristic is equal percentage, that is, with the change of the valve opening, the flow change shows a stable and equal proportional relationship, which makes the segment ball valve very suitable for applications requiring fine control of flow. The adjustable ratio is up to 100:1, which means that the flow rate can change continuously from full on to near full off, providing a wide range of adjustment. The ball adopts 1/4 hemispherical shape with unilateral seat structure. When there are solid particles in the medium, the cavity blockage will not occur like ordinary O-type ball valves. There is no gap between the segment ball and the seat, which has a large shear force, especially suitable for the control of suspension and solid particles containing fiber or small solid particles. Because segment ball valves are often used for the control of corrosive media, they are usually made of corrosion-resistant materials, such as stainless steel, alloys, etc., to ensure long-term stable use. Segment ball valve in the fluid through, because the cavity in the ball body is V-shaped, the fluid flows through the large pressure loss, so it is suitable for high pressure loss requirements. When the ball valve passes through the fluid, the pressure loss is relatively small because the cavity in the ball body is a circular groove. |

| Technical Parameters | |

| Size | DN15-DN1500, 1/2''-60'' |

| Pressure | PN10-PN420, Class150-Class2500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Wafer, Thread, Socket weld, Butt weld |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc |