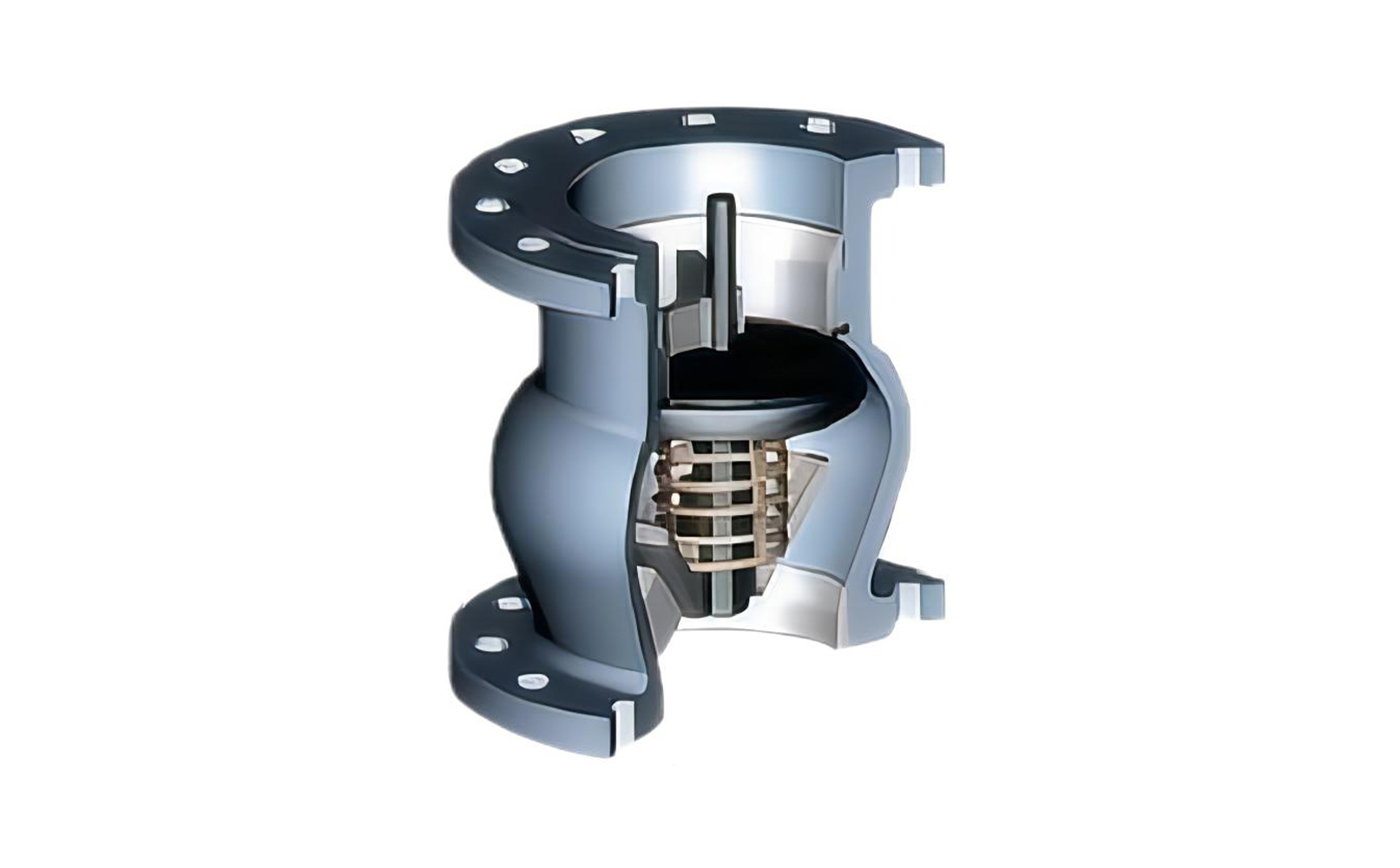

- 01The slow closing design can reduce noise and vibration in the pipeline system, improve the working environment and equipment service life.

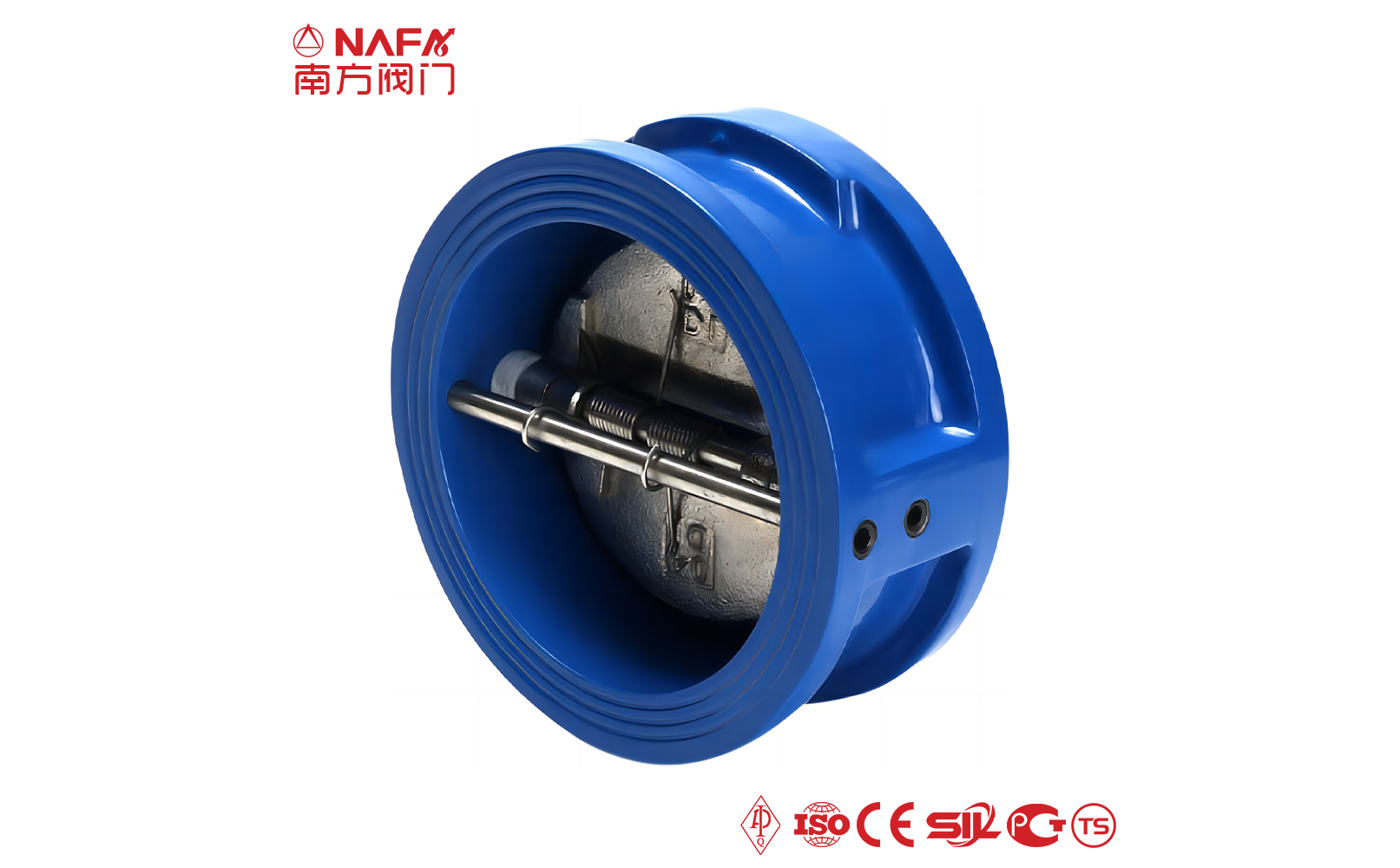

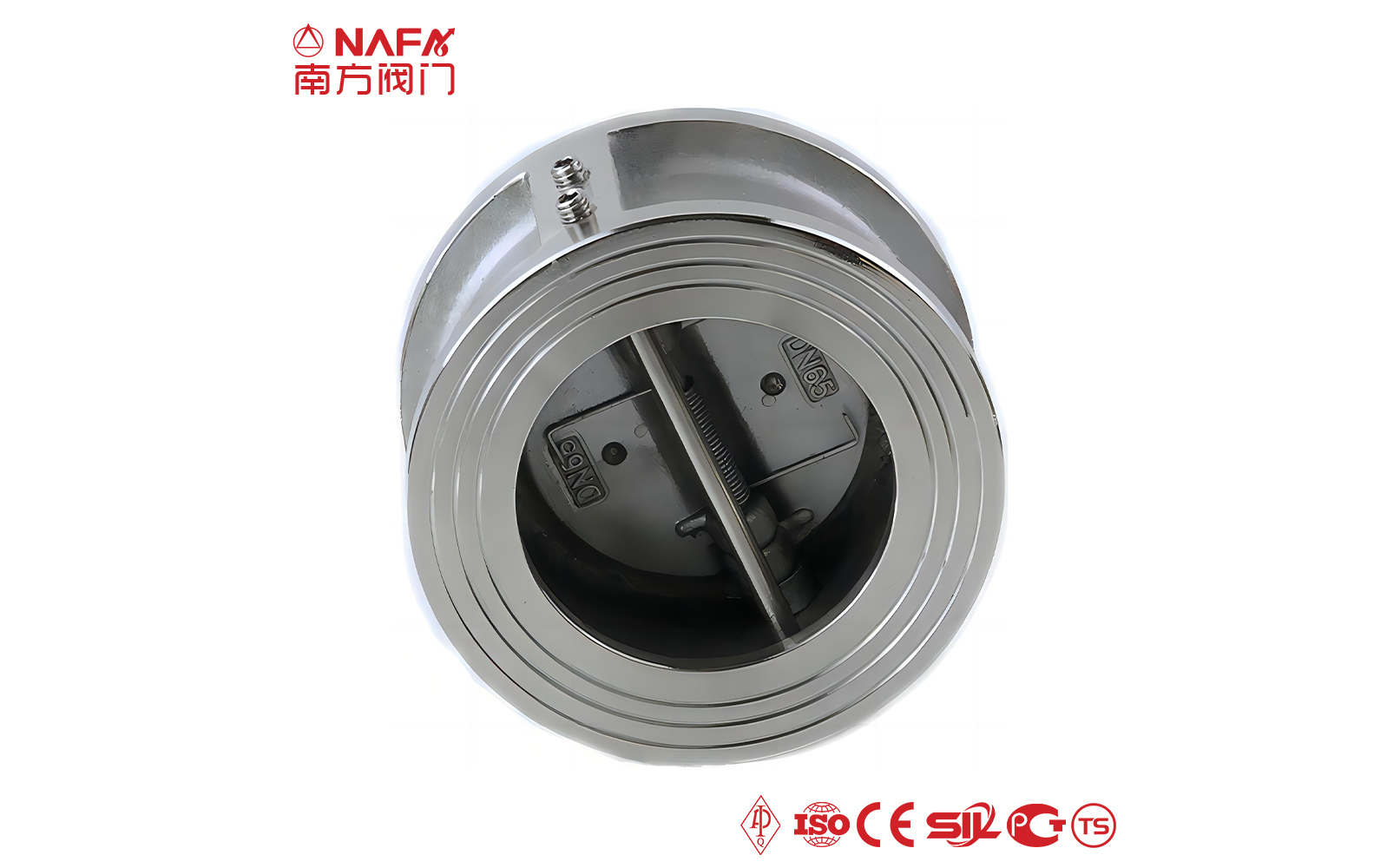

- 02Small size and light weight, its weight is only 1/4~1/20 of the traditional flange check valve.

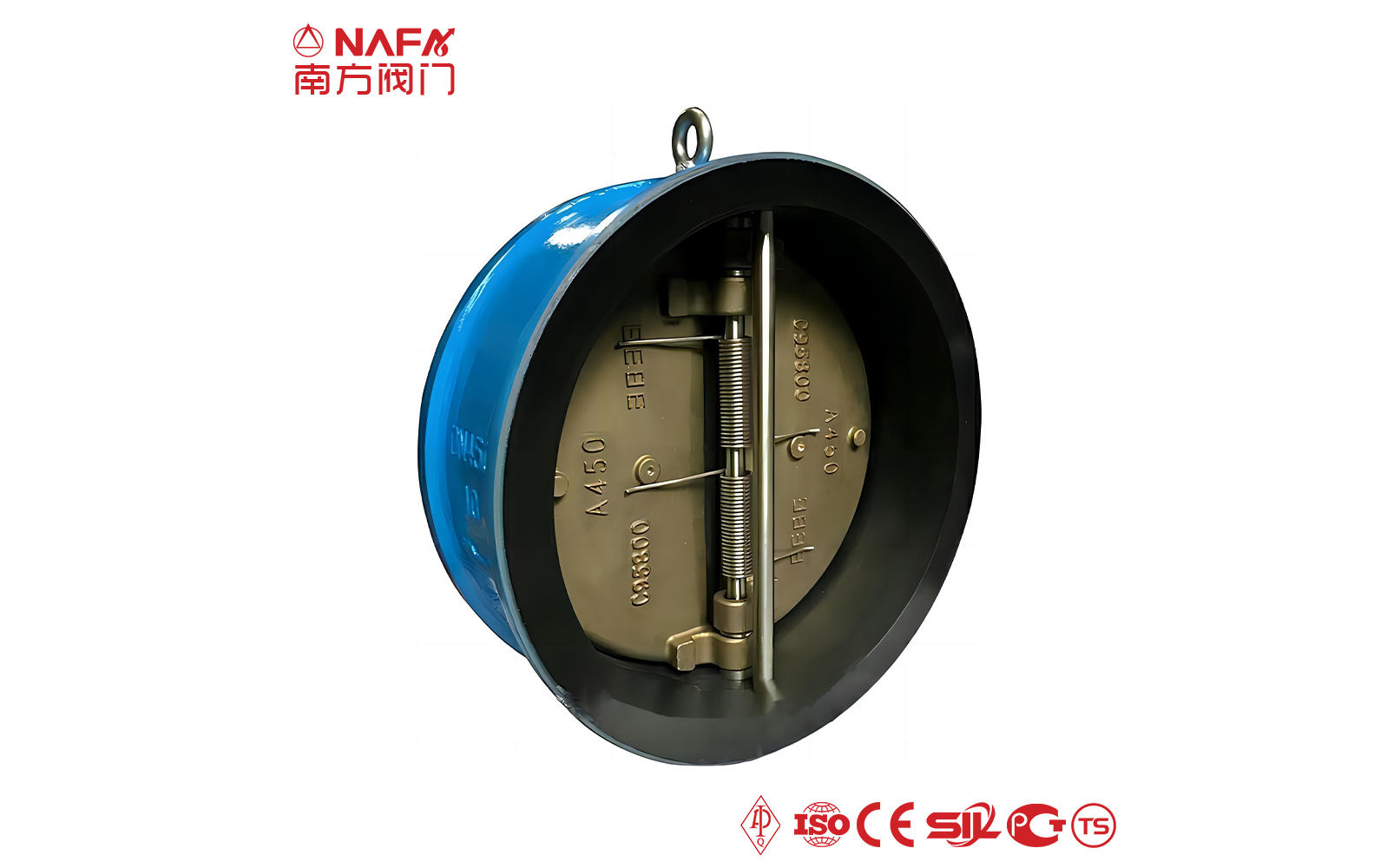

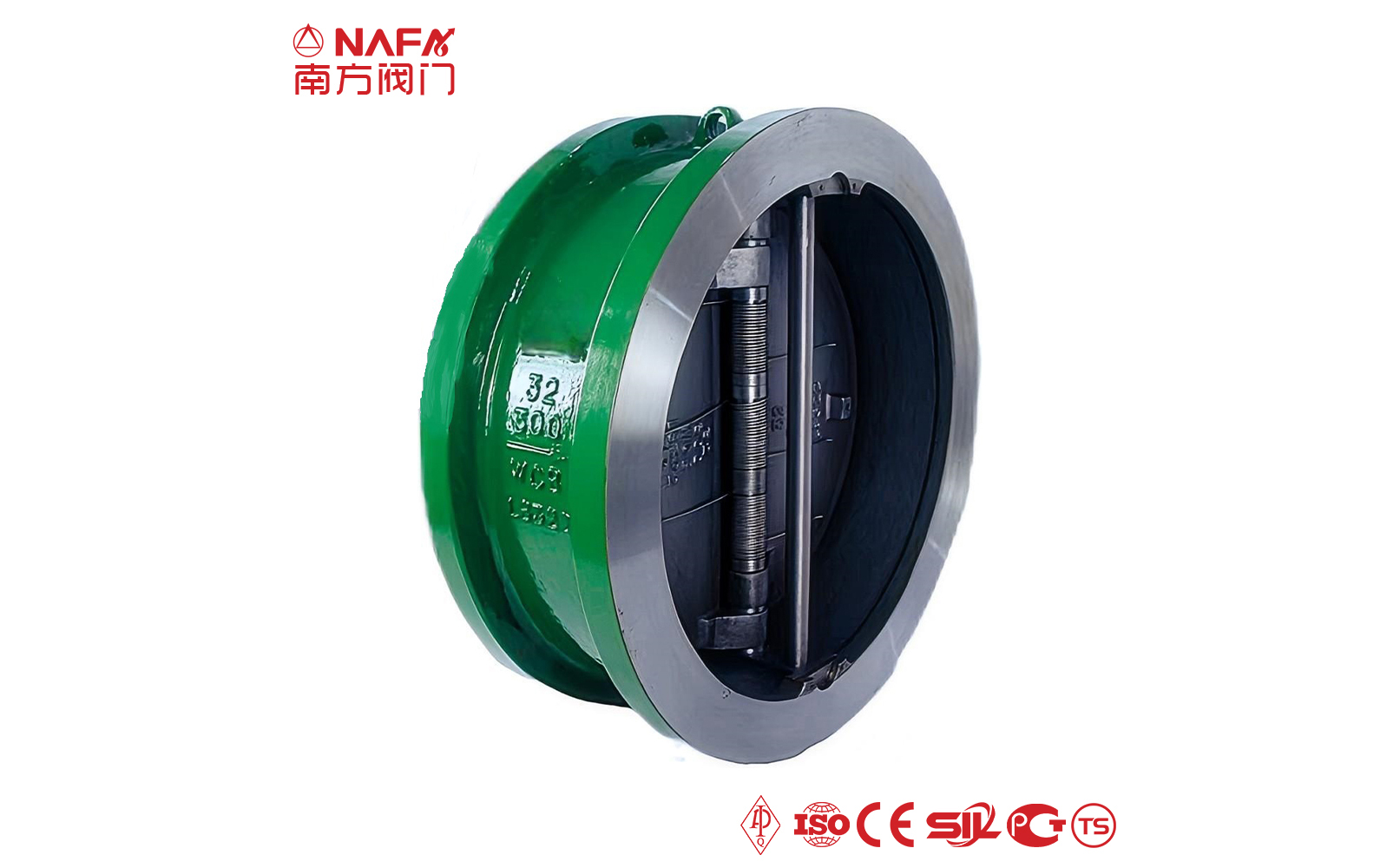

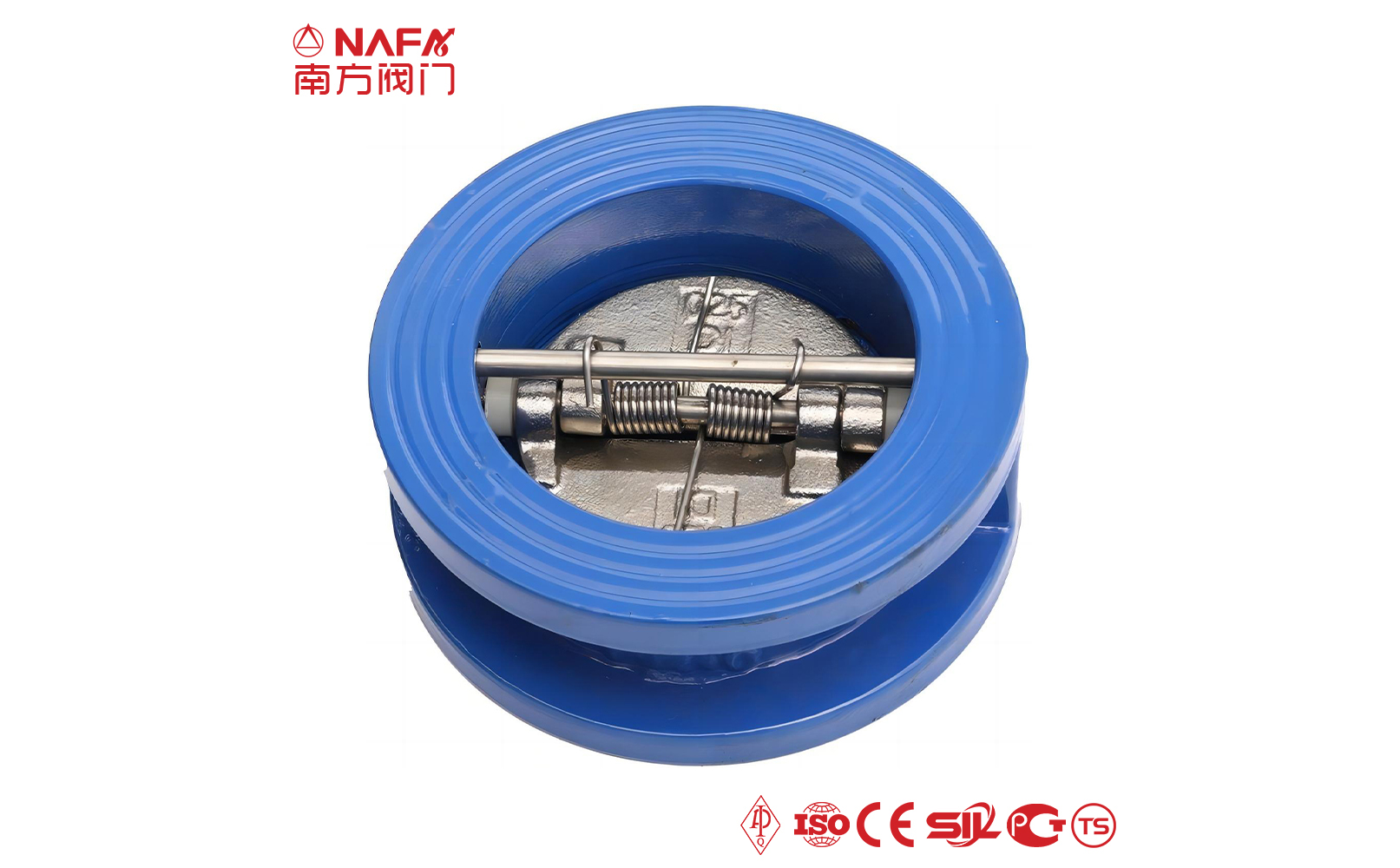

- 03The double-flap check valve disc closes quickly and has low water hammer pressure.

- 04Both horizontal and vertical pipelines can be used, and installation is convenient.

- 05The double-flap check valve has smooth flow and low fluid resistance.

- 06The double-flap check valve disc has a short stroke and low impact force.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

| The characteristics of double disc check valve |

The double disc structure uses two spring-loaded valve discs suspended on a central vertical chain pin. When the fluid begins to flow, the valve disc opens under the combined force acting on the center of the sealing surface. The point of action of the spring support force that acts as a reaction is located outside the center of the valve disc surface, so that the root of the valve disc opens first. This avoids the friction of the sealing surface that occurs when the valve disc is opened in the old conventional valve, eliminating the wear of the components. The valve seat is inclined, the butterfly plate (valve disc) drive shaft is assembled horizontally and is located above the axis of the valve channel, so that the total area of the butterfly plate below the rotating shaft exceeds the upper end. When the material stops flowing or flows back, the butterfly plate rotates to the valve seat by its own weight and the action of the countercurrent material. When closing, the action of the spring force point causes the top of the valve disc to close first, preventing the root of the valve disc from biting and rubbing, allowing the valve to maintain the sealing integrity for a longer time. |

| Technical Parameters | |

| Size | DN15-DN1500, 1/2''-60'' |

| Pressure | PN10-PN420, Class150-Class2500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Wafer, Welded |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc |