- 01The spherical closing part can automatically position at the boundary position.

- 02The closing part can withstand the high pressure difference when closing.

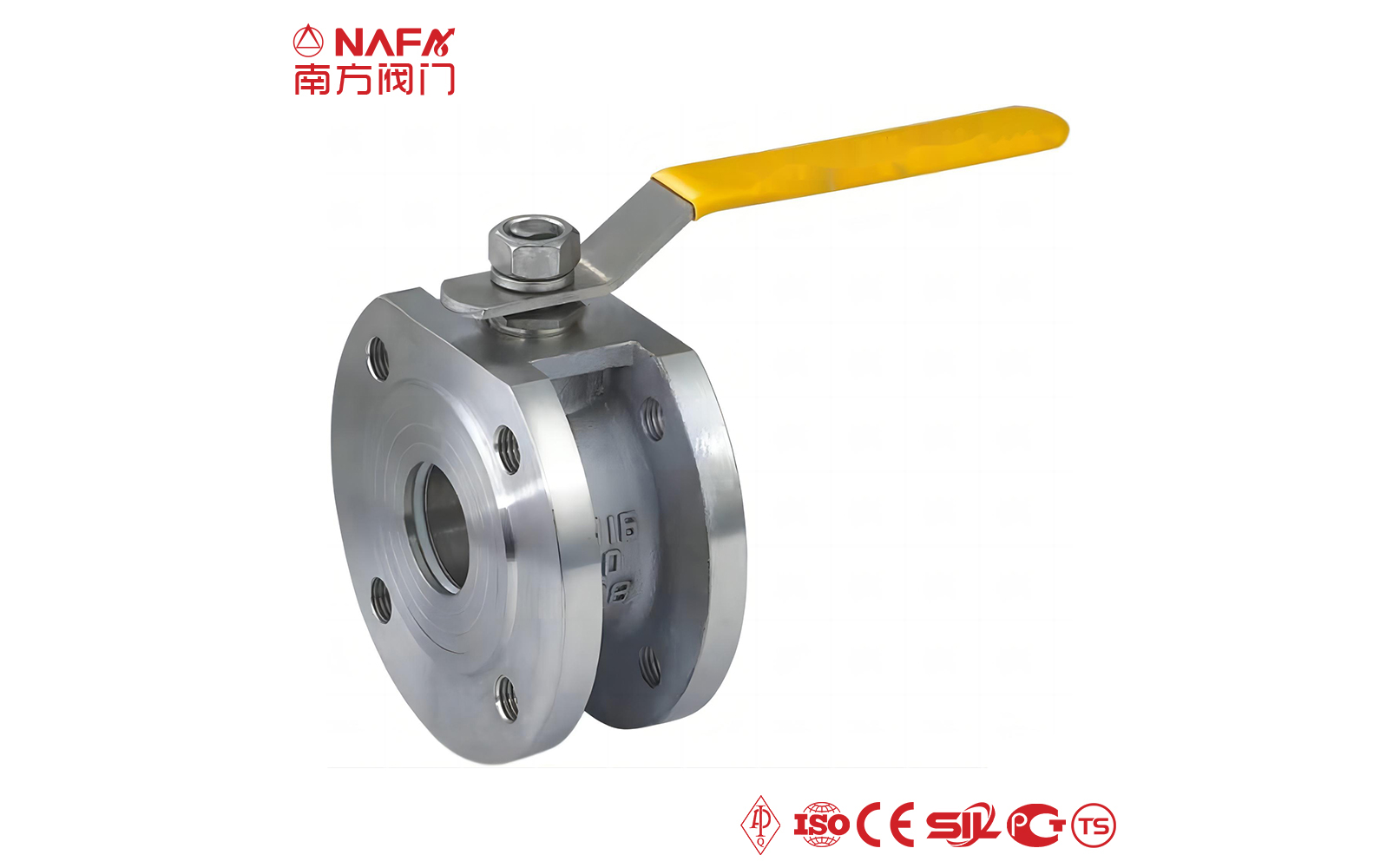

- 03The thin ball valve shortens the flange spacing of the ball valve, saves assembly and installation costs, is more compact than the ordinary flange ball valve, and avoids the leakage of the medium from the middle flange connection of the valve.

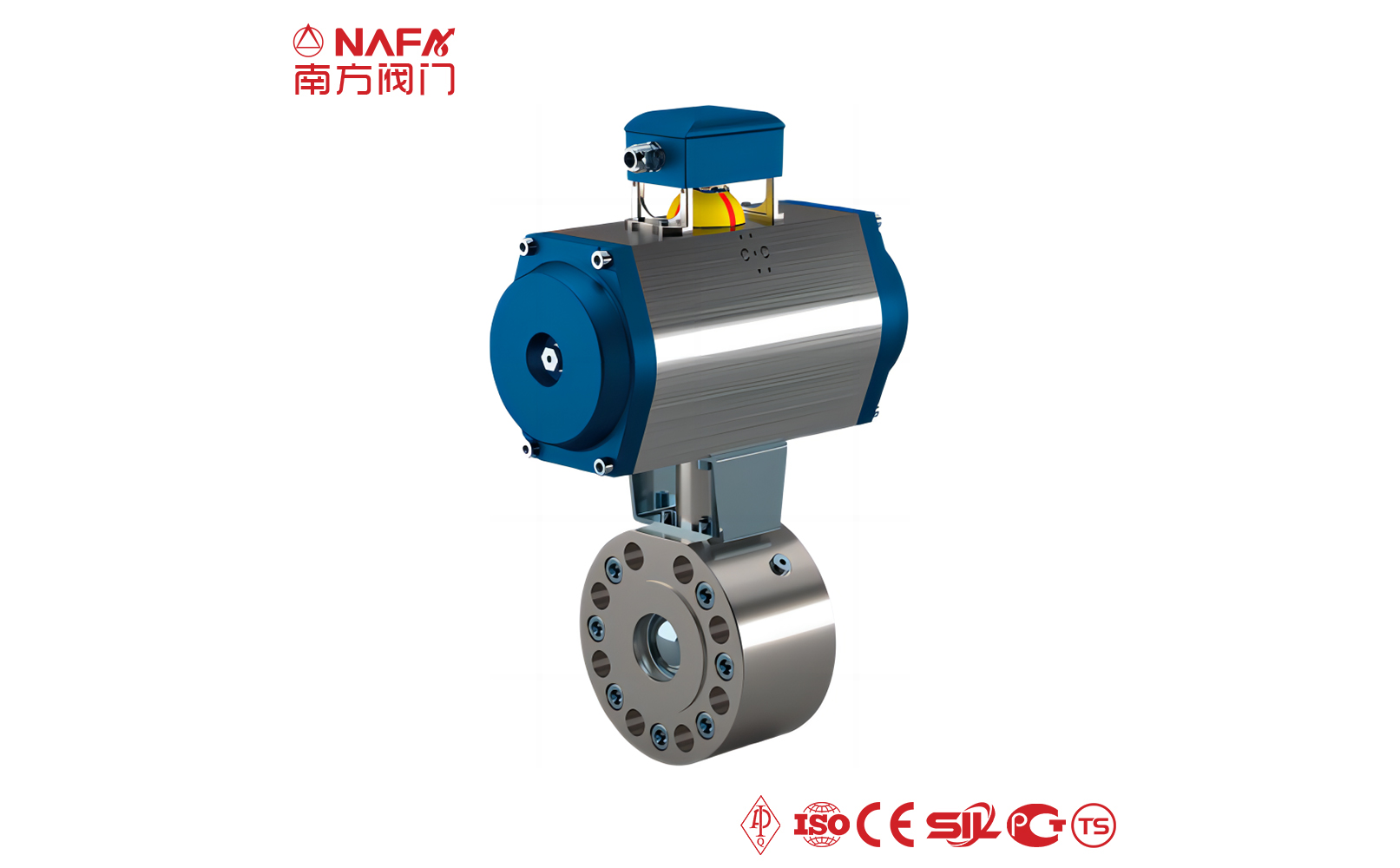

- 04The high platform design forms a pneumatic thin ball valve with a pneumatic actuator, or forms an electric thin ball valve with an electric actuator to meet the needs of automatic control in the system.

- 05The valve body material is usually selected from materials with good corrosion resistance, such as stainless steel, copper alloy, etc.

- 06Complete sealing can be achieved over a wide range of pressures and temperatures.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

| The characteristics of thin ball valve |

It is mainly used to control the fluid in the pipeline and can be widely used in liquid and gas control systems. It can realize fast switching operation and is suitable for occasions requiring frequent opening and closing. Due to the good sealing performance between the ball and the valve seat, it can maintain good sealing performance even in high temperature, high pressure and corrosive media environments. The pneumatic thin ball valve controls the rotation of the ball through the pneumatic actuator to achieve fluid switching control. When the pneumatic actuator applies pressure, the sealing surface between the ball and the valve seat is completely closed or opened. The position of the ball is controlled by adjusting the pressure of the air source to achieve fluid on-off and regulation. The electric thin ball valve can receive switching signals to cut off the pipeline medium, and can also receive analog signals 4-20mA, etc. to adjust the flow rate of the pipeline fluid. |

| Technical Parameters | |

| Size | DN15-DN1500, 1/2''-60'' |

| Pressure | PN10-PN420, Class150-Class2500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Wafer, Welded |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc |