- 01TExcellent bidirectional sealing performance and small torque value.

- 02Flow characteristics tend to be linear and have good adjustment performance.

- 03Flange connection is easy to be installed, whether vertically or horizontally.

- 04Diversity of sealing materials for users to choose.

- 05The valve can be used as a vent valve at the pipe end with reliable performance.

- 06The valve seat seal ring is organically integrated with the valve body, giving the valve a long service life.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

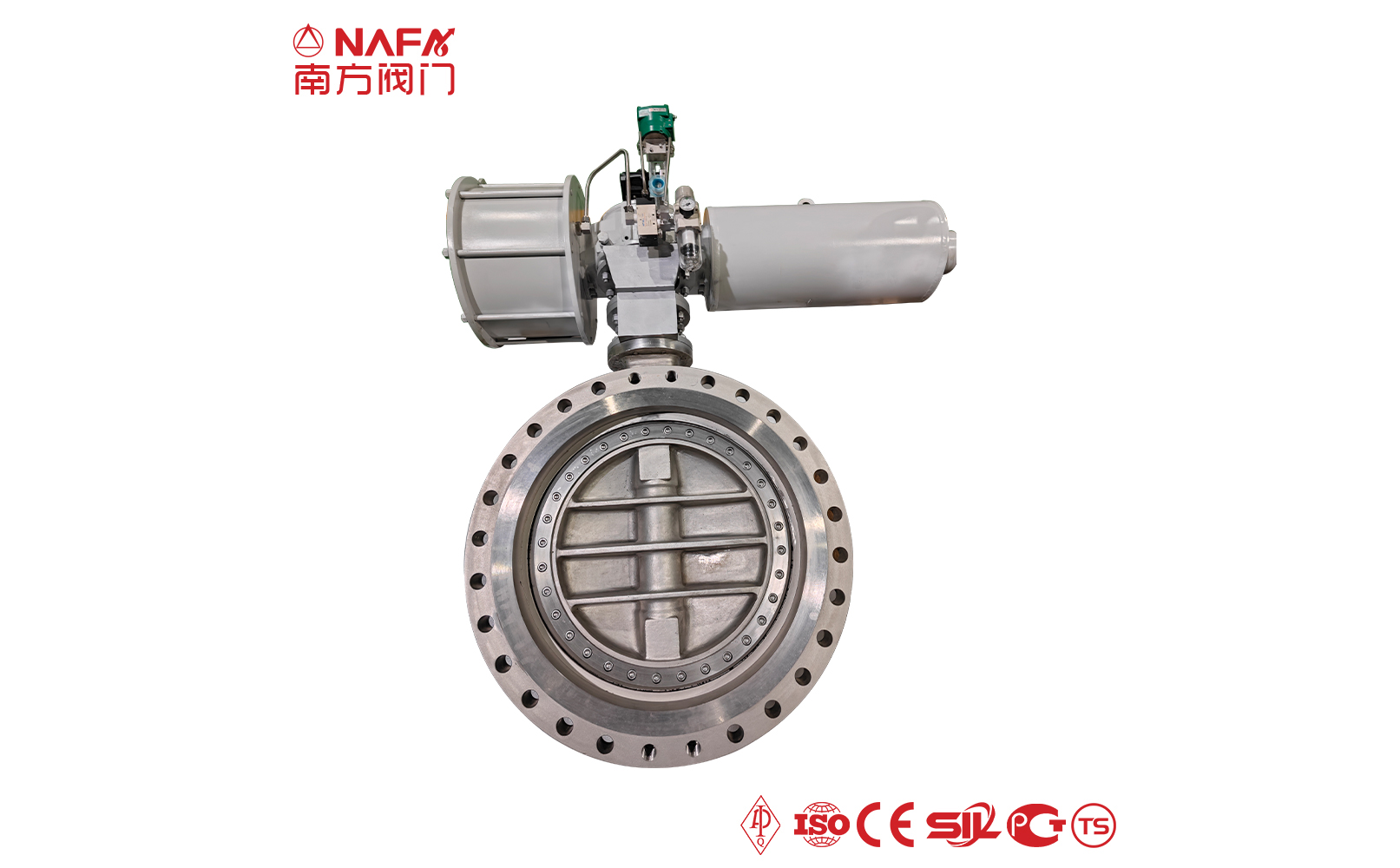

| The characteristics of bidirectional butterfly valve |

The butterfly plate adopts a unique streamlined structural design, and the total thickness does not exceed 2 times the diameter of the valve stem. The butterfly plate has good strength under positive and negative pressure, and will not cause harmful permanent deformation and damage under 1.1 times the maximum allowable pressure difference. The large-diameter butterfly plate adopts a truss structure and has high fluid dynamics characteristics and low flow resistance coefficient. The connection design between the valve stem and the butterfly plate adopts an eccentric pin structure. The eccentric pin structure improves the stress condition of the connecting pin, greatly improves the shear resistance of the pin shaft, and calculates and checks the load when opening and closing under 1.5 times the maximum pressure difference to ensure that the diameter and number of the pin shaft connecting the butterfly plate and the valve stem meet the transmission requirements. The valve can realize bidirectional pressure bearing without medium flow direction requirements, and the positive and negative pressure bearing capacity can reach 1:1, which increases the application range of the valve. When the valve is used in underground pipeline systems such as direct burial and valve wells, the valve operation platform interface can be heightened according to different customer needs. |

| Technical Parameters | |

| Size | DN15-DN1500, 1/2''-60'' |

| Pressure | PN10-PN420, Class150-Class2500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Wafer, Welded |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc. | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc. | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc. |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc. |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc. |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc. |