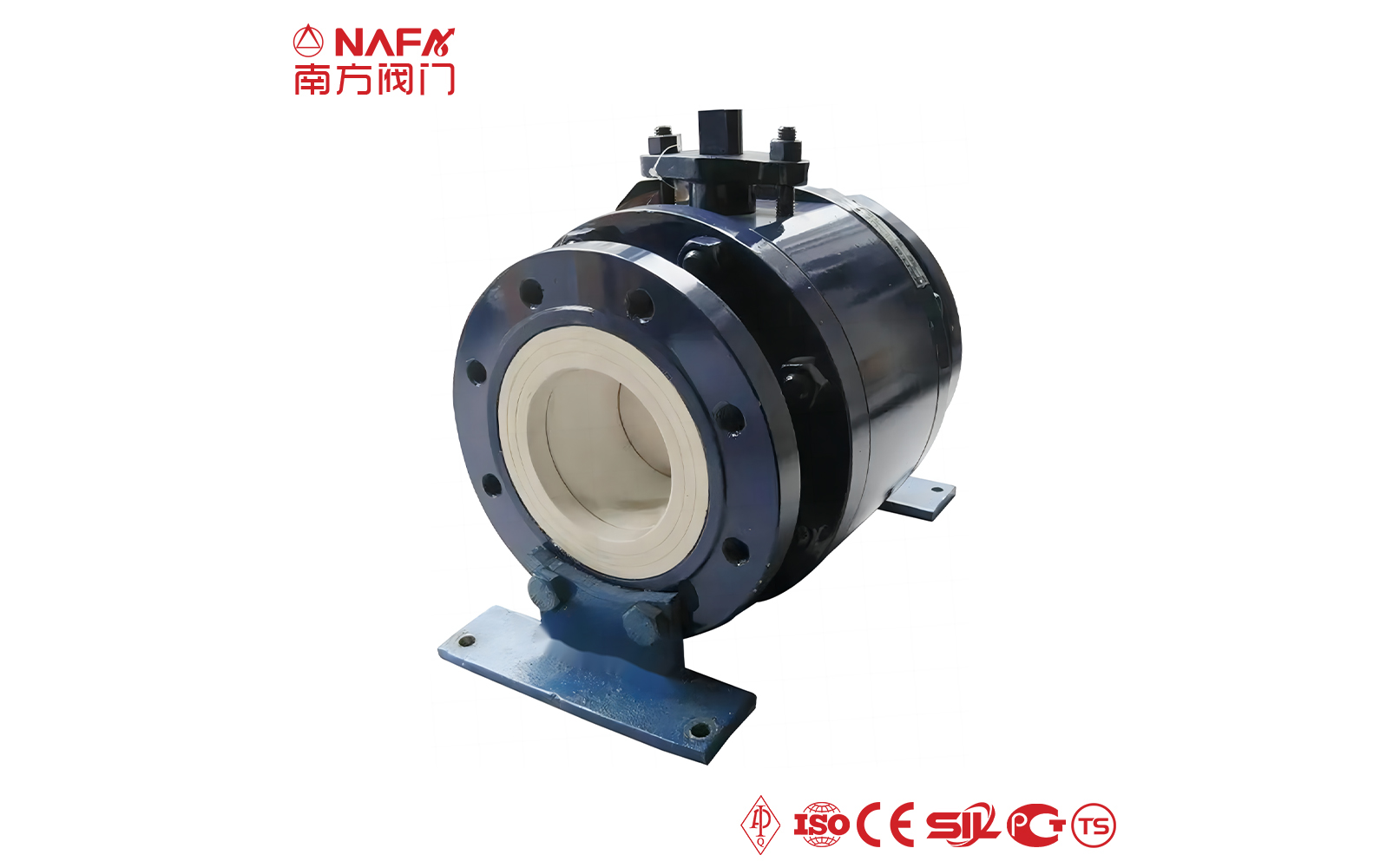

- 01Ceramic ball valves use high-tech new materials (alumina, zirconium oxide) as seals.

- 02Corrosion-resistant, erosion-resistant, and not easy to wear.

- 03Built-in buffer compensation elastic gaskets ensure stable and good sealing. And in the medium containing impurities, it is not easy to get stuck and cause the ball to break.

- 04Ceramics have high compressive strength, high wear resistance, excellent oxidation resistance and corrosion resistance, high temperature resistance, and good thermal insulation performance.

- 05The ball has high roundness. After grinding with the valve seat, the self-lubricating property of structural ceramics is used, the opening and closing torque is small, and it has excellent sealing performance.

- 06The flow channel and the middle body are fully lined with structural ceramics, which can effectively avoid the erosion of the flow channel and the valve body due to high flow rate and high solid content.

-

API

API -

АСМЕ

АСМЕ -

АНСИ

АНСИ -

RU

RU -

ДИН

ДИН -

ГОСТ

ГОСТ -

ГБ

ГБ -

JIS

JIS

| The characteristics of ceramic ball valve |

All parts in contact with the medium are made of structural ceramic materials, and their chemical stability and hardness (Rockwell hardness HRC90) are second only to diamond. Therefore, this valve has excellent wear resistance, corrosion resistance, erosion resistance, good heat insulation and small thermal expansion. The ball is manufactured using advanced grinding equipment and technology, with high ball roundness accuracy and good surface quality. After grinding with the valve seat, the self-lubricating property of Zr02 ceramics can be used to achieve good sealing performance. The good wear resistance of ceramics makes this valve durable and very stable. It is 2-4 times more durable than titanium valves and monel valves. This type of valve has incomparable advantages in high-toughness granular media, or media with soft particles but corrosive, and is also suitable for such media. |

| Technical Parameters | |

| Size | DN15-DN1500, 1/2''-60'' |

| Pressure | PN10-PN420, Class150-Class2500 |

| Temperature | -200°C to 650°C |

| Connection Type | Flange, Thread, Socket weld, Butt weld |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic, Gear operation |

| Materials | ||

| Valve Body | Forged | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, etc |

| Cast | WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Valve Stem | F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500, N08020, Inconel625, Incoloy825, etc | |

| Valve Disc | A105, LF2, F5, F9, F11, F22, F304, F316, F347, F904, F51, F53, F310, N08020, Inconel625, F6a, 17-4PH, XM-19, F304, F316, F347, F904, F51, F53, F310, Monel400, Monel500,Incoloy825,WCB, LCB, C5, C12, WC6, WC9, CF8, CF8M, CF8C, 4A, 5A, CN7M, C95800, CW6MC, etc | |

| Seat Sealing | SS, BR, CU, AS, CS, AL, PTFE, NBR, FKM, AI203, etc | |

| Design Standards | |

| Valve Body | API 6D, API 608, ASME B16.34, DIN 3357, BS 5351, GOST 9833, JIS B2071, GB/T 12237, etc |

| Flange | ANSI B16.5, EN 1092-1, JIS B2220, GB/T 9113, ASME B16.47, GOST 12821, DIN 2543-2545, etc |

| Connection | ANSI B16.10, ASME B16.25, JIS B2212, GOST 33259, DIN 3202, etc |

| Test Standards | API 598, ISO 5208, BS EN 12266, ASME B16.104, GOST 9544-2015, JIS B2003, DIN 3230, etc |