South Valve Technology Co., Ltd. расположена в уезде Юнцзя, городе Вэньчжоу, провинции Чжэцзян, реке Оуцзян, опирающейся на горы и воду, красивые пейзажи. Компания была основана в 1997 году, является первой партией частных предприятий по производству клапанов в Китае, компания осуществляет постоянные инновации и исследования и разработки, стремится стимулировать развитие всей отрасли.

Постоянная разработка новых продуктов, а также независимая разработка программного обеспечения для управления, через формирование многолетних знаний в области управления и эксплуатации и развития технологий прочности основы, продолжать укреплять разработку интеллектуальных интеллектуальных продуктов и интеграцию и применение передовых технологий, расширять масштабы производства и изменять модель продаж, а также активно исследовать рынок.

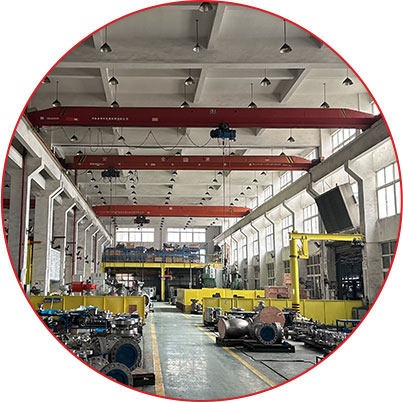

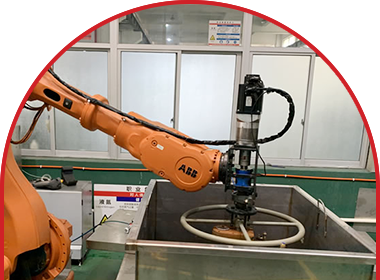

С момента своего расширения в 2012 году NAFA создала крупномасштабные базы обработки и производства в трех городах, охватывающие общую площадь около 20 000 квадратных метров, с самыми передовыми пятикоординатными обрабатывающими центрами и различными типами станков с ЧПУ, передовыми автоматическими сварочными аппаратами, плазменными сварочными аппаратами, 300KVA 2,5×2 ×1,5m высокомощными, высокопроизводительными термическими печами. Имеется более 100 комплектов контрольно- испытательного оборудования, такого как Belec Compact Port спектрометр с прямым считыванием для мгновенного тестирования, -196℃ устройство для испытания на удар при низкой температуре и универсальная машина для испытания материалов с ЧПУ.

На сегодняшний день компания South Valve Technology Co., Ltd. стала квалифицированным и отличным поставщиком пяти основных энергетических групп Китая, трех нефтяных групп Китая (Sinopec, China National Petroleum Corporation, China National Offshore Oil Corporation) и других всемирно известных предприятий Китая. Ряд технических показателей в отрасли на передовом уровне и получила патент на изобретение.